My previous best efforts to make my own large faced copper nuts for lots of surface area between nut and stud, and ring terminal to nut, were less than stellar, but my best results were accomplished by not running the tap all the way through, and then letting the stud itself form the remainder of the threads. Hardening the cut threads with superglue or epoxy, and the pullout strength is impressive, as well as being resistant to moisture intrusion/ wicking.Ĭopper is a strange medium to work with.

Thank you for your efforts to share your knowledge in such a precise, concise yet detailed manner, It is much appreciated.ĭue to having a lot of Stainless machine screws on hand, I have been drilling and tapping wood with impressive results, even soft plywoods.

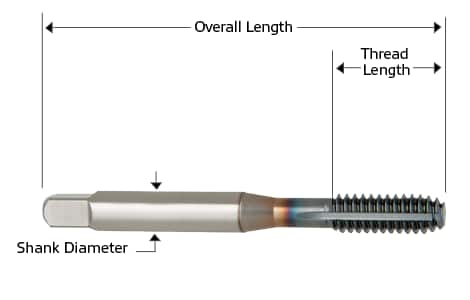

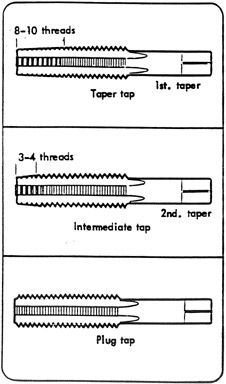

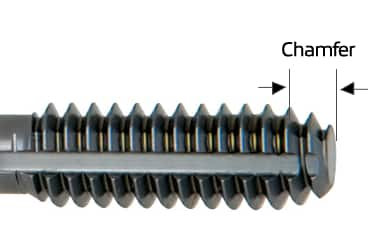

Your response is likely the most helpful response to any question I have ever posted on the internet. I have included an example of a form tap drill chart for reference. Use the form tap drill sizes that your tap manufacturer recommends. Note that recommended form tap drill sizes will vary from manufacturer to manufacturer. Manufacturers will typically provide a matrix of form tap drill sizes based on the percentage of threads that are formed. With copper being the material for this application, the form tap will be much more forgiving than say, a stainless steel. Thread forming taps are generally harder for shade tree type guys to work with and are more likely to break during use.įor OP's circumstances cut threads are completely acceptable.įWIW tap drill sizes for the OP's application are as follows:įorm tap drill sizes will vary depending on the formability of the material. Thread forming taps require a slightly larger tap drill than a standard cutting tap to account for the fact that the threads are formed by deforming the material as opposed to removing (cutting) the material. Thread forming taps are typically used where very strong threads are required. I have linked an excellent overview of tap styles and when each style is appropriate to use. Chip direction (forward or reverse) is driven by the geometry at the tip of the tip. The number of flutes has zero impact on the direction the chips move. The one 3/8" hole drilled so far will be accepting a 3/8-16 bolt whose receptacle is the load/source side of a 500 amp Deltec shunt.Ĭlick to expand.Respectfully, this is not accurate information. The Brass bolt heads will not be easy to access, and I'd rather not even attempt to solder such a thick mass of copper to lock them in place I'd love to be able to bottom out the brass bolts, and then not have to worry about soldering them, or securing their heads so that I do not need to use two wrenches to tighten the ring terminals against the bar. So this 3/8" thick, 1 inch wide copper bar is overkill, which means its just about right. I am making my Own Bussbar, for 2/0 cable, which will rarely see a maximum sustained current of 240 amps. With No experience using thread forming taps, I am wondering if they pull themselves into the predrilled hole, or if they have to be lowered/ forced into the predrilled hole with precision I can never achieve by hand. Researching this, I ran across the recommendation to use thread forming taps rather than thread cutting taps. I've drilled and tapped copper before without a drill press, for 6mm metric thread ( nippondenso alternator + output stud), but was less than impressed with the results.

What is the difference between cutting tap and forming tap upgrade#

I'm Looking to make 3/8-16 threads in a 3/8" thick chunk of copper, for some brass bolts to make my own upgrade proof busbar.

0 kommentar(er)

0 kommentar(er)